Applied innovation to transform industry

The Professional Master’s Program in Materials Processing at Universidade do Vale do Paraíba is designed for professionals and researchers seeking to enhance their technical and scientific skills in the development and application of advanced materials. For over a decade, the program has fostered a strong connection with the productive sector in the pursuit of solutions to real-world challenges faced by industries across various sectors, such as metallurgy, aerospace, automotive, oil and gas, chemical, electronics, civil construction, biomedical, among others.

Why choose our Professional Master’s Program?

✔ Curriculum structure: Courses provide a solid foundation in materials science fundamentals, scientific research methods, innovation, and entrepreneurship.

✔ Industry focus: Research projects are guided by real demands from the productive sector.

✔ State-of-the-art infrastructure: Well-equipped laboratories for advanced experimentation.

✔ Highly qualified faculty: Professors with both academic and industry experience.

✔ Industry connections: Strategic partnerships with leading companies, startups, and innovation clusters.

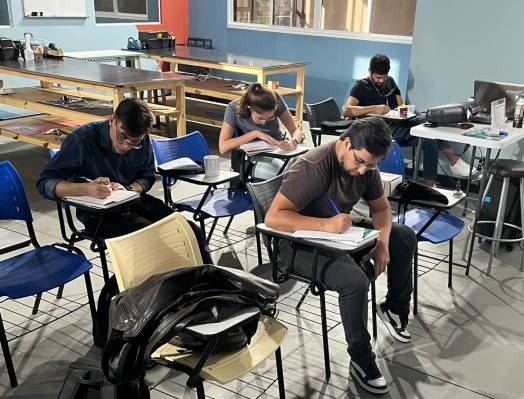

✔ Flexibility: Class schedules compatible with working professionals.

THE PROGRAM TRAINS PROFESSIONALS TO THRIVE IN A MARKET FACING A GROWING SHORTAGE OF QUALIFIED LABOR, WHILE DEMANDING INCREASINGLY HIGHER LEVELS OF TRAINING!

Application Areas

Throughout its existence, the PPGPM has graduated professionals through the development of projects aimed at diagnosing problems and proposing solutions in the following areas, among others:

🔹 Automotive Sector: Diamond-like carbon (DLC) coatings for fuel tanks to reduce or eliminate corrosion, microbial growth, and adhesion.

🔹 Oil & Gas Sector: Synthesis of the conductive polymer polypyrrole on carbon steel surfaces using the electrochemical method in acetonitrile organic solvent with various dopants and assessment of its anticorrosive performance.

🔹 Civil Construction: Mortar using ground glass waste as a substitute for fine aggregate.

🔹 Aeronautics and Aerospace: Electrodeposition of polypyrrole films on aluminum alloy surfaces to prevent corrosion.

🔹 Electronics Industry: Application of graphene to optimize the electrical conductivity of aluminum conductor bars in busway systems.

🔹 Biomedical Engineering: Production and characterization of hybrid PDLLA/bioactive glass scaffolds.

🔹 Numerical Computing: Development of numerical simulations for plastic waste reuse.

Market Connection

Our master’s program partners with national and multinational companies to develop applied projects in technological innovation. Students have the opportunity to conduct research aligned with the needs of the productive sector, expand their professional network both in quality and quantity, develop patents, foster innovation within companies, and even build the innovative core of their own startup.

Univap hosts its own Technology Park, home to more than 50 technology-based companies in diverse fields such as structural engineering, aerospace, aeronautics, robotics, cosmetics, solar energy, logistics, and more. This proximity allows incoming students without a predefined research project to align their studies with one of the partner companies.

The institution also houses a Business Incubator, where innovative and entrepreneurial ideas developed during the master’s program can be solidified and matured to compete in the market as active economic players, generating innovation, income, and employment.

Target Audience

This program is designed for engineers of all specialties, physicists, chemists, technologists, and other professionals from the industrial and health/biological sectors who seek to deepen their knowledge of materials, manufacturing processes, and their effects on properties and industrial applications.

Coordination

Ivone Regina de Oliveira

ivonero@univap.br

Fernando dos Santos Ortega

Vice coordinator

ortega@univap.br

Andreza Ribeiro Simioni

simioni@univap.br

Erika Peterson Goncalves

erika@univap.br

Leandro José Raniero

lraniero@univap.br

Liu Yao Cho

liu@univap.br

Lúcia Vieira

lucia.vieira@univap.br

Milton Beltrame Júnior

beltrame@univap.br

José Geraldo da Cruz Pradella

pradella@univap.br

Wagner Anacleto Pinheiro

anacleto@univap.br

• PROPERTIES AND PROCESSES OF MATERIALS AND COMPOSITES: METALS, CERAMICS, AND POLYMERS

The properties of metallic, ceramic, polymeric, glass, and composite materials depend on their chemical composition and the presence of additives capable of modifying these properties, but are also strongly influenced by the manufacturing process. In this context, the works classified under this research line aim to provide students with tools to understand the relationship between structure and properties of materials applied in multiple engineering sectors, such as mechanical, civil construction, oil and energy, aeronautics, and biomedical fields. The physical and chemical properties of raw materials and processed materials are studied through sophisticated investigative techniques, enabling students to establish correlations between components, products, manufacturing processes, and properties. Special attention is given to topics related to environmental impacts, through multiple approaches, such as the recycling of solid waste—adding value and reintegrating it into the product life cycle; the development of biopolymers and biodegradable systems capable of minimizing environmental impact when disposal is unavoidable, as in biomedical products; and increasing product lifespans, such as through the development of corrosion protection systems for metallic alloys or concrete resistant to the harsh environments of wastewater treatment plants. The student gains a holistic view of the material life cycle, encompassing its design, raw material selection, the most appropriate manufacturing process, evaluation of relevant properties, and reuse at the end of its useful life.

• BIOMATERIALS AND NANOTECHNOLOGY

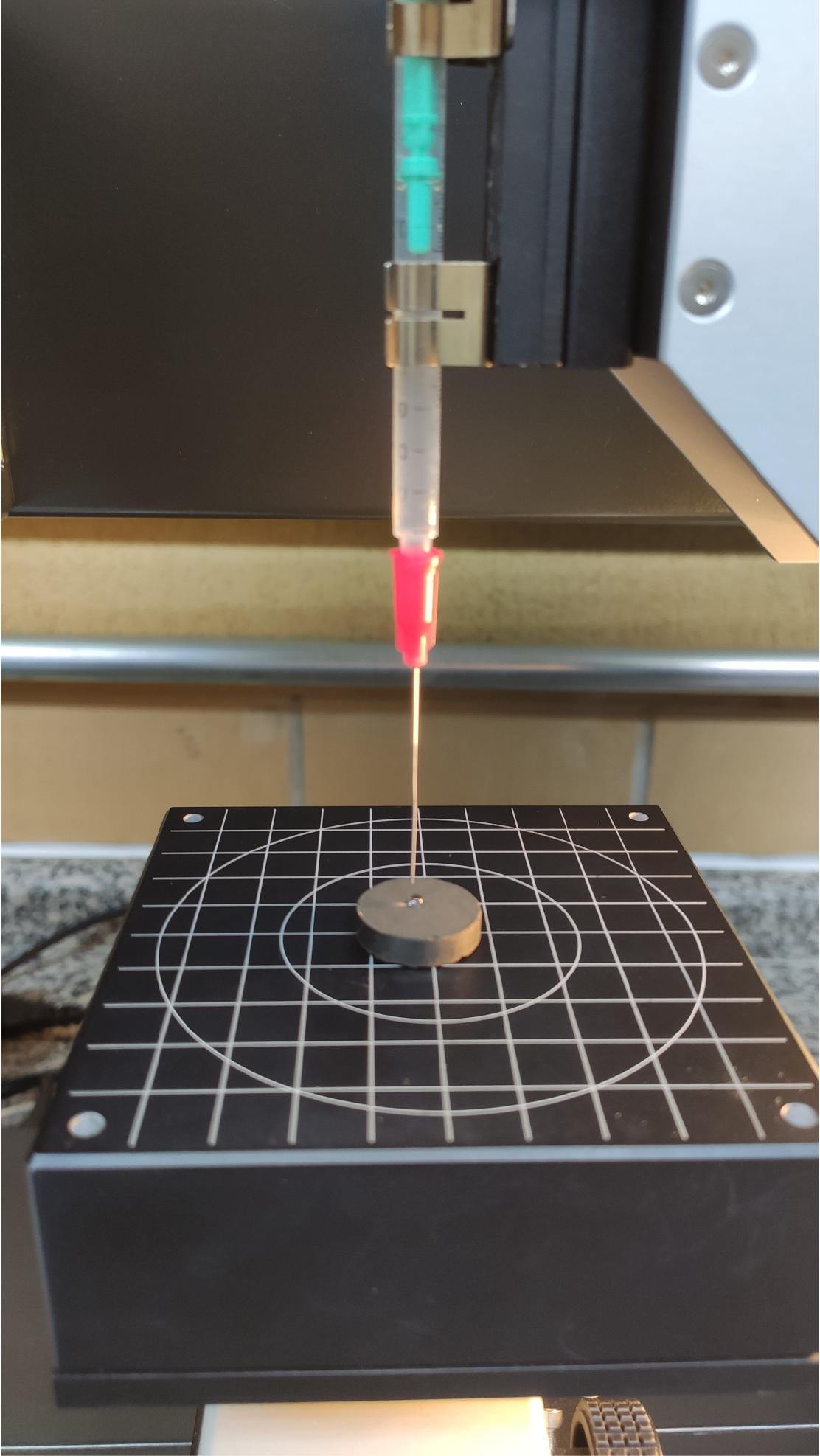

This line involves the study and subsequent development of substances, classified as biomaterials, intended to control interactions with living components in procedures aligned with major therapeutic and/or diagnostic areas. The projects developed by the PPGPM involve the synthesis, processing, and characterization of biomaterials that are biocompatible with different material classes and their respective composites. These materials have wide applicability and attract significant scientific interest from the medical-pharmaceutical industry for purposes such as tissue regeneration or stimulation of new tissue growth. In terms of applications, micro- and nanostructured systems are being developed and characterized for use in photodynamic therapy; bio-printing materials like hydrogels and bioinks; ceramic-based blends for bone repair; bio-composites in lyophilized or bioprinted scaffolds for bone grafts; microspheres or nanofibers; immobilized cell and enzyme systems; nanodrugs for diagnosis and treatment of diseases; and drug delivery systems for controlled release. The developed biomaterials must promote cell adhesion, differentiation, and proliferation, and encourage the production of specific molecules for the tissue in question. This scientific field can assist in developing new drug application processes and mechanisms, aiming to make treatments less aggressive and invasive to the patient’s body—thus, making these drugs more effective. Nanotechnology, however, is not limited to the biological field and can also support the development/optimization of materials, giving them new properties that may be widely applicable in industries such as automotive, aerospace, manufacturing, electronics, and others. Beyond the focus on improvement and development of new materials and preparation routes, the research conducted here also addresses the evaluation of environmental and biological impacts of nanomaterials.

• INDUSTRIAL TECHNOLOGIES FOR AERONAUTICAL, ENVIRONMENTAL, CIVIL, CHEMICAL, AUTOMOTIVE, AND RELATED APPLICATIONS

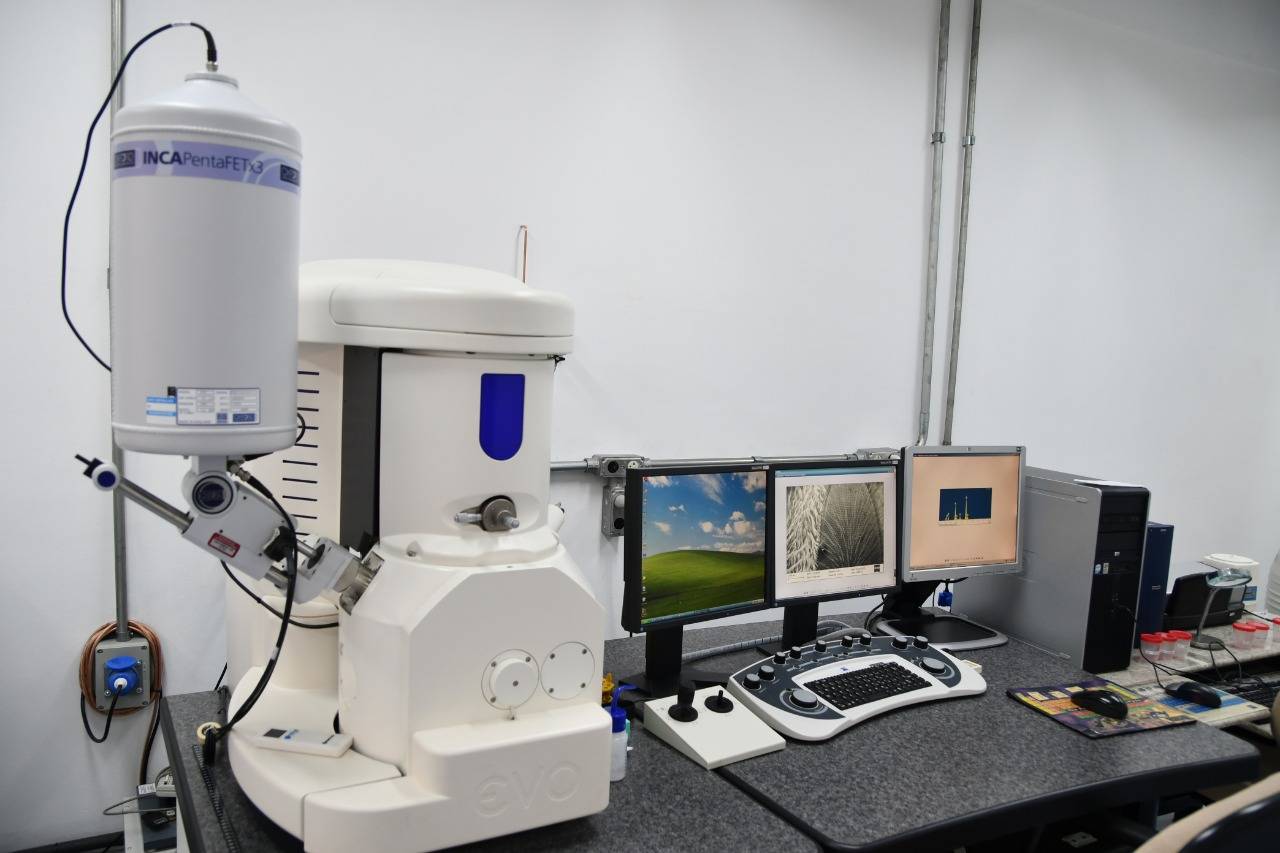

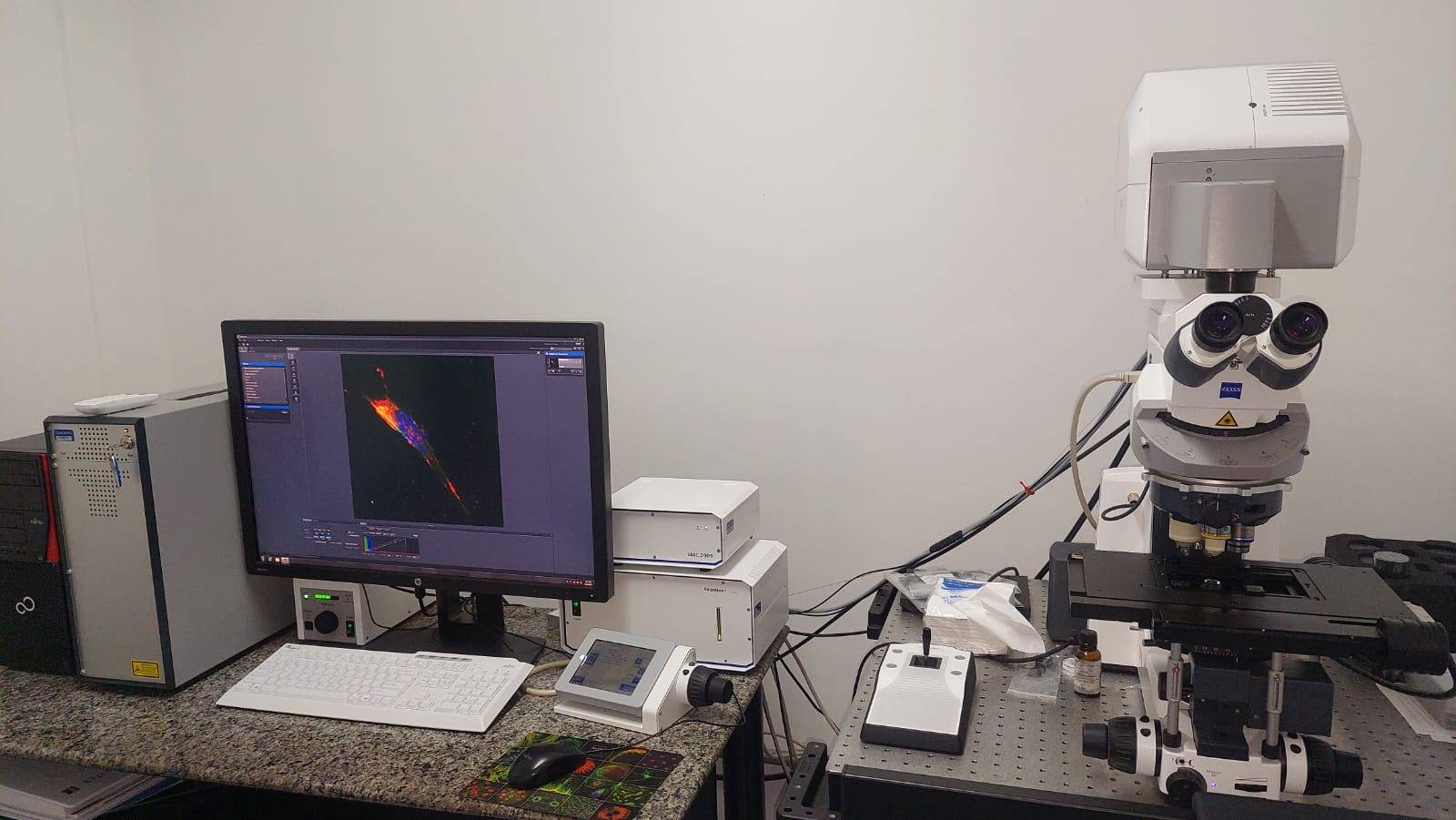

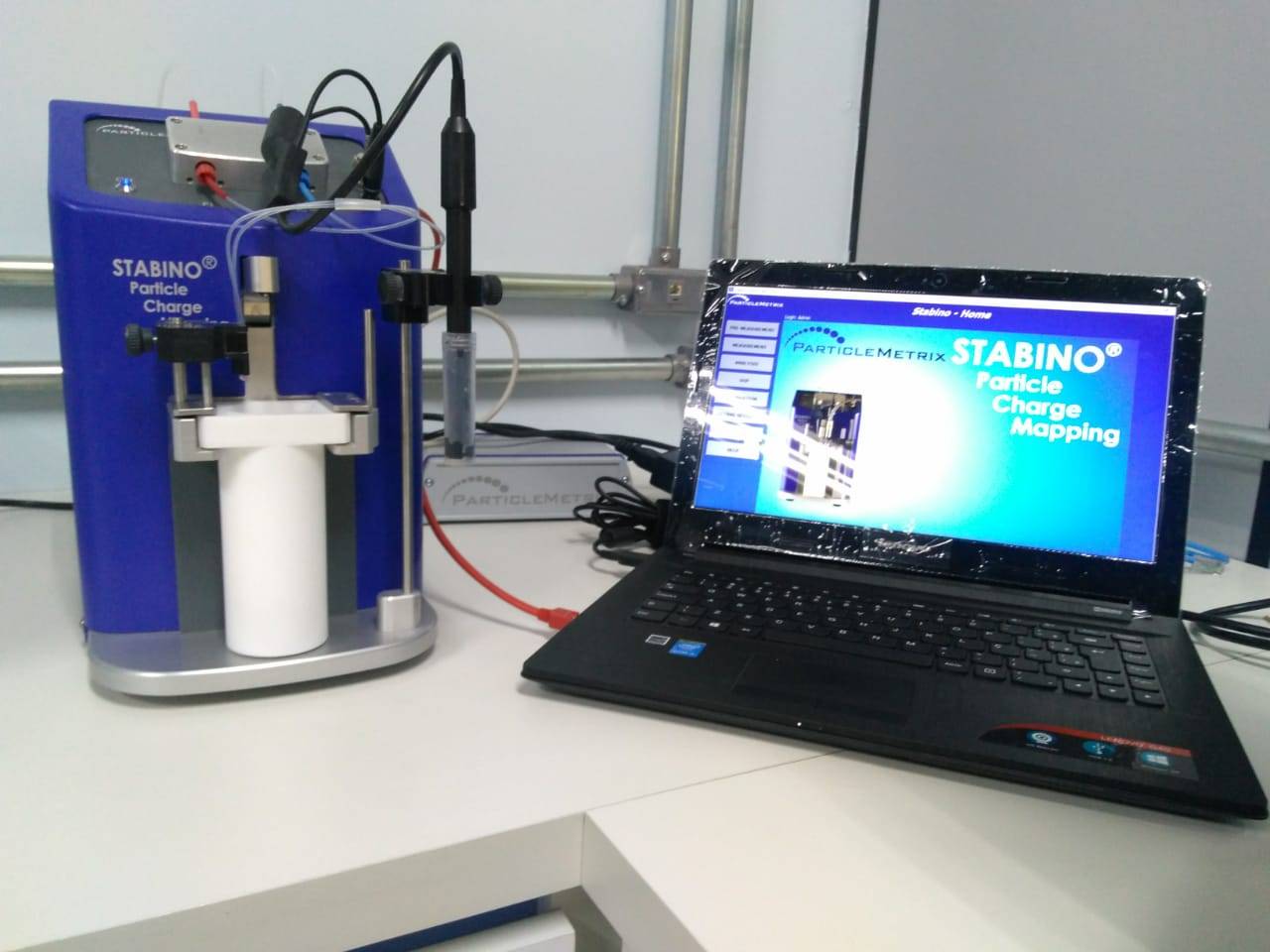

The study of materials and their properties is inherent to human nature and lies at the heart of Engineering: shaping the world around us to meet society’s demands, with respect for people and the environment. Given today’s highly complex technological markets, the industry increasingly faces challenges in optimizing products to meet market demands. Therefore, this research line involves the study of new technologies applied to industrial processes in the aeronautical, environmental, chemical, oil, automotive, and related sectors. Projects in this area focus on real-world problem-solving based on industry needs regarding their products and processes—whether manufacturing, quality, development of new products, or new production processes—as well as predictive or corrective failure analyses. Given the wide range of analysis possibilities—enabled by equipment such as rheometers, SEMs, FTIRs, mechanical testing machines, zeta potential analyzers, etc.—students can develop proposals for optimizing or correcting properties and structures by analyzing materials on a bulk or nanometric scale. They will obtain data and indicators to improve mechanical, electrical, chemical, and optical properties, ensuring the material is optimized for the scale economy or scope relevant to the industrial niche of the research project, all while meeting regulations and customer demands.

1) Completion of 12 credits in mandatory courses and 9 credits in elective courses, totaling 21 credits required in coursework.

2) Completion of 9 credits in the elaboration of the dissertation, demonstrating the scientific and technological challenges involved in the project and the means and methods employed to overcome them. A total of 30 credits is required to obtain the Master's degree in Materials Processing.

MANDATORY COURSES

Materials Science and Technology | 3 credits

Historical perspective, interactions (processing–structure–properties–performance), criteria for materials selection. Structure of crystalline solids. Defects in solids. Introduction to phase diagrams. Metallic materials. Ceramic materials. Polymeric materials. Material properties.

Thermodynamics of Materials | 3 credits

Structure of thermodynamics: classification of thermodynamic systems; thermodynamic variables; equilibrium criteria. Laws of thermodynamics: 1st law of thermodynamics; 2nd law of thermodynamics; relation between entropy transfer and heat; 3rd law of thermodynamics. Thermodynamic variables and relations: thermodynamic definitions (H, F, and G); Maxwell relations; thermodynamic relationships. Equilibrium of thermodynamic systems. Unary heterogeneous systems. Surface and interfacial tension; solid-liquid transition by nucleation and growth. Capillary pressure and solid-state sintering; grain growth in crystalline solids. Multicomponent systems, homogeneous and heterogeneous; construction of binary and ternary equilibrium diagrams.

Entrepreneurship and Innovation | 2 credits

Entrepreneurship. Interdisciplinary and transdisciplinary research. Innovation management. Quality management in research and innovation. Intellectual property. Trademarks and patents. Science & Technology legislation.

Scientific Research Methodology | 2 credits

The process of scientific investigation. Research and its classifications. Scientific methods. Research project (dissertation or thesis). Elaboration and presentation of the research report (dissertation or thesis). How to write technical-scientific reports or articles for publication.

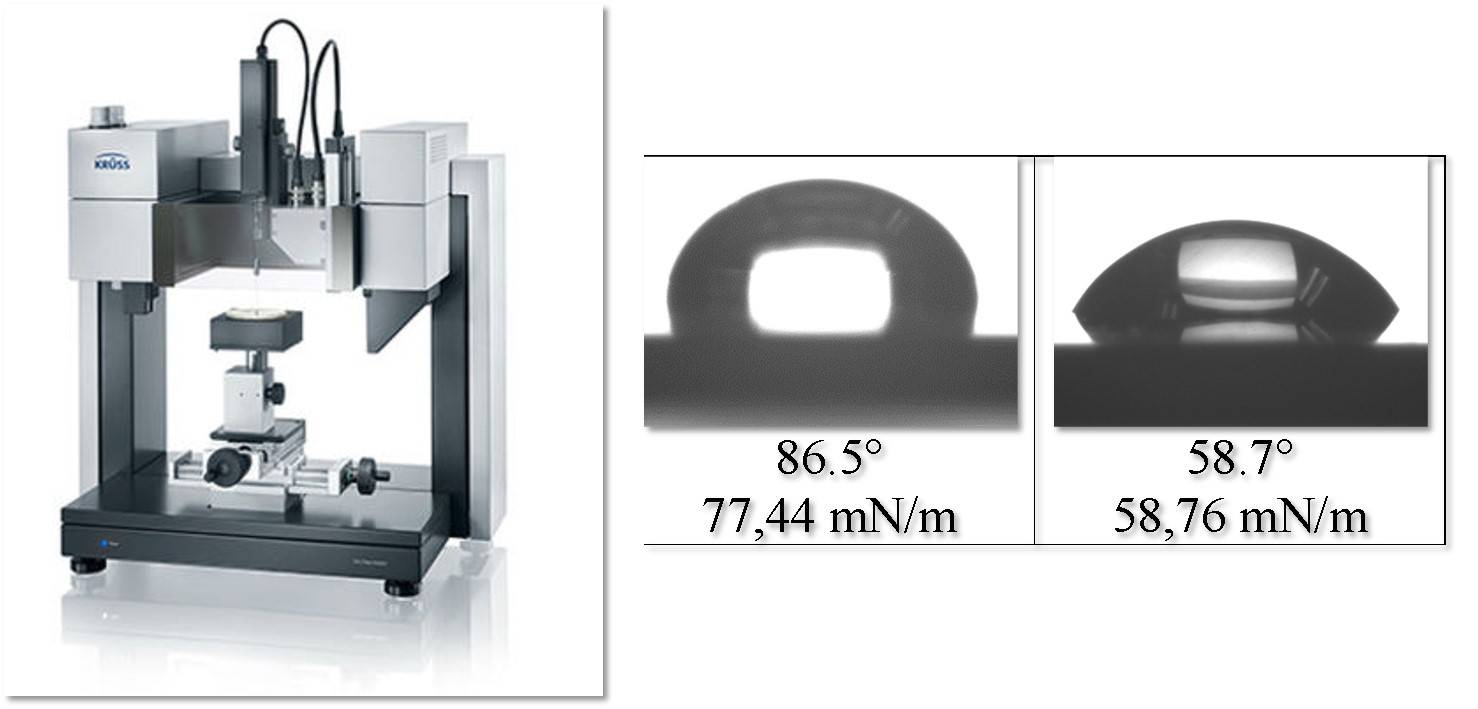

Experimental Topics in Material Characterization Techniques | 2 credits

Material characterization through the combination of various techniques: main concepts, definitions, and data analysis. FTIR, visible and UV light spectrometer, scanning electron microscope, X-ray diffraction, Raman spectroscopy, particle size analysis (DLS, Laser), mercury porosimetry, BET, helium pycnometry, zeta potential, mechanical testing, thermal analysis, tribology, contact angle, among others.

ELECTIVE COURSES

Metallic Materials: Processing, Properties, Application, and Characterization | 3 credits

Metals and Metal Alloys: Properties and Applications. Fracture Mechanics. Metallic Systems. Phase Transformations in Metals. Hardening Mechanisms in Metals. Ferrous Alloys. Non-ferrous Alloys. Applications.

Ceramic Materials: Processing, Properties, Application, and Characterization | 3 credits

Ceramic structures. Defects and diffusion. Phase diagrams. Interfaces. Analysis and characterization. Processing, microstructure, and properties of ceramics. Applications.

Polymeric Materials: Processing, Properties, Application, and Characterization | 3 credits

Basic concepts of macromolecules. Polymerization reactions. Polymer classification. Thermoplastics. Thermosets. Elastomers. Conductive polymers. Blends. Structure-property relationships. Polymer processing. Polymer characterization. General properties and applications.

Composite Materials | 3 credits

Introduction to composite materials: definitions and basic concepts. Types of matrices: polymeric, metallic, ceramic, and carbon-based. Reinforcements: particulates, whiskers, and synthetic organic, inorganic, and natural fibers. Adhesion and reinforcement/matrix interface. Manufacturing processes of polymeric, metallic, and ceramic composites, properties and applications. Structural composites.

Corrosion and Degradation of Materials | 3 credits

Corrosion and its economic and social importance. Corrosion of metals and alloys. High-temperature degradation. Degradation of polymers and ceramics. Corrosion protection.

Nanoscience and Nanotechnology of Materials | 3 credits

History and basic concepts of nanotechnology. Introduction to miniaturization and scale analysis. Synthesis and properties of nanomaterials and nanoparticles. Nanobiotechnology. Social, economic, and ethical implications of nanotechnology.

Topics in Materials Technology | 3 credits

Discussion of current and relevant technological topics in the field of materials and processes. Product development and process improvement.

Biomaterials | 3 credits

History and definitions. Introduction to natural and synthetic biomaterials—metallic, ceramic, and polymeric. Biomaterials selection and development. Required properties. Materials for reconstruction and/or replacement. Characterization of biomaterials: physicochemical, mechanical, and biological. Biomaterials sterilization and presentation forms.

ELECTIVE COURSES

Dissertation Seminars | 2 credits

This course aims to develop the ability to provide and receive constructive feedback on a research project, incorporating ideas and opinions into the work while evaluating the relevance, clarity, and objectivity in presenting the details of the project and product.

Extension Practice | 2 credits

Extension. Interdisciplinary actions among graduate programs. Professional knowledge and university life. Solid waste treatment. Use of environmental liabilities.

The Graduate Program in Materials Processing (PPGPM) has access to several laboratories directly related to the field of Materials, located at the Institute for Research and Development (IP&D), where students can carry out their research under the guidance of the program’s faculty.

In addition, at the School of Engineering, Architecture and Urbanism (FEAU) at Univap, there are 45 teaching laboratories, 15 of which are connected to the areas of concentration of the PPGPM. These are well-equipped teaching laboratories, capable of supporting a wide range of tests and experiments, upon prior authorization from the FEAU administration and under the supervision of the academic advisor.

The following laboratories, located at IP&D or FEAU, support the PPGPM (according to the Institutional Development Plan – PDI 2021–2025).

• Multiuser Laboratory Center – IP&D

• Advanced Materials Development Laboratory – IP&D

• Tissue Repair and Biostimulation Laboratory – IP&D

• Infrared Spectroscopy Laboratory – IP&D

• Bionanotechnology Laboratory – IP&D

• Bioprocesses Laboratory – IP&D

• Heterogeneous Catalysis Laboratory – IP&D

• High-Performance Computing Laboratory – IP&D

• Organic Electrochemistry Laboratory – IP&D

• Applied Photobiology for Health Laboratory – IP&D

• Nanosensors Laboratory – IP&D

• Nanotechnology and Plasma Processing Laboratory – IP&D

• Dentistry and Applied Materials Laboratory – IP&D

• Micro and Nanoparticulate Systems Laboratory – IP&D

• Hybrid Composites Technology Laboratory – IP&D

• Industrial Chemical Processes Laboratory – FEAU

• Biotechnological Processes Laboratory – FEAU

• General Chemistry Laboratory – FEAU

• Multidisciplinary Laboratory of Technological Innovation – FEAU

• Soil Mechanics and Pavement Engineering Laboratory – FEAU

• Composite Materials Laboratory – FEAU

• Materials Processing Laboratory I – FEAU

• Materials Processing Laboratory II – FEAU

• Materials Processing Laboratory III – FEAU

• Materials Characterization Laboratory I – FEAU

• Materials Characterization Laboratory II – FEAU

• Materials Characterization Laboratory III – FEAU

• Extraction and Corrosion Laboratory – FEAU

• Plasma Laboratory – FEAU

• Construction Technology and Structural Systems Laboratory – FEAU

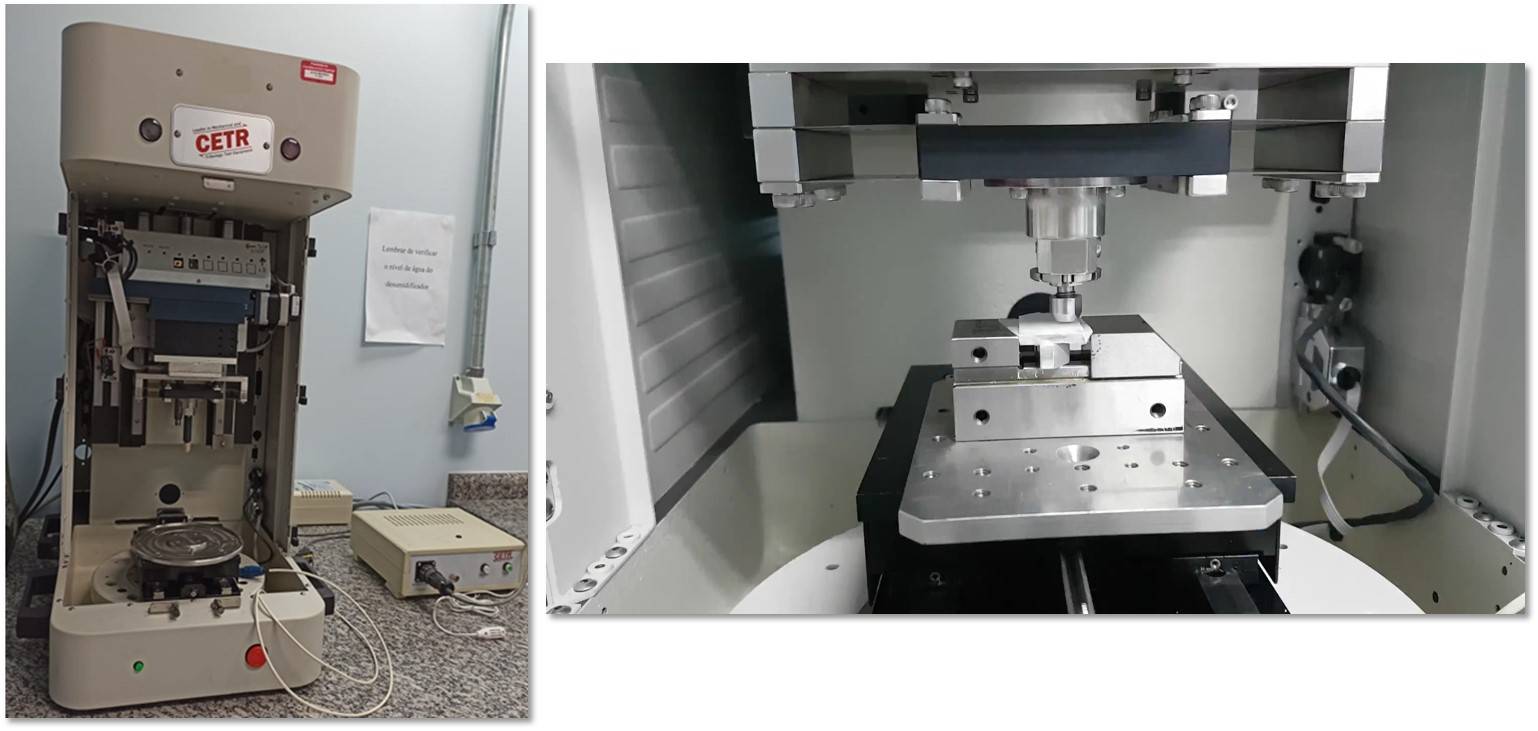

All these laboratories are well-structured and equipped with a comprehensive array of modern equipment and systems, offering PPGPM students a unique opportunity to become familiar with various techniques for sample study, preparation, and characterization. Some of the notable equipment available in these laboratories include:

• Professional PECVD reactor for thin film deposition (Nanomaster Inc.);

• Atomic Layer Deposition Reactor (TFS-200, BENEQ);

• Molecular Beam Mass Spectrometer (HPR-60, Hidden);

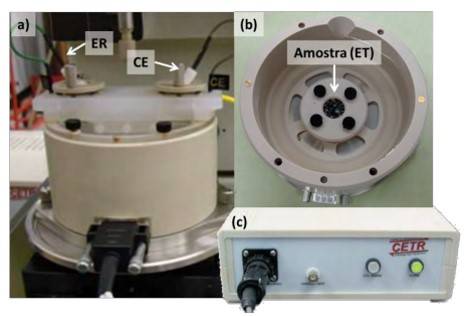

• Tribometer (UMT-CETR);

• Scanning Electron Microscope (ZEISS EVO MA10);

• X-ray Diffractometer (XRD-6000, Shimadzu);

• Automatic Vicat Apparatus (Vicatronic E044-Solotest);

• Photodensitometer for measuring optical density (O.D.);

• High-energy mill Pulverisette 5 (Fritsch GmbH) with sintered corundum grinding bowls;

• Micro planetary mill Pulverisette 7 (Fritsch GmbH) with zirconia grinding bowls;

• Controlled atmosphere chamber (humidity and oxygen control) with loading antechamber for materials and reagents;

• Potentiostat/Galvanostat connected to a computer with cells and electrodes;

• Gas/Liquid Chromatograph (GLC) Shimadzu CG-17A with fiber optic connected to a computer;

• System for fractional distillation and vacuum drying of reagents;

• Potentiostat/Galvanostat Autolab 128N with temperature and pH module;

• Potentiostat/Galvanostat Autolab 302N with impedance, temperature, and pH module;

• Automatic goniometer (Kruss 100S);

• Infrared Spectrometer Spectrum 400 (Perkin Elmer);

• Infrared Spectrometer Spectrum 2000 (Perkin Elmer);

• Energy-Dispersive X-ray Fluorescence Spectrometer model micro EDX 1300 (Shimadzu);

• Atomic Absorption Spectrophotometer model ANALYST 200/1;

• UV-VIS Absorption Spectrophotometer Lambda 25 UV WINLA (Perkin Elmer);

• Universal Rheometer model MARS 40 (Haake);

• Haake Rheometer: model HAAKE Viscotester iQ AIR (Thermo Electron);

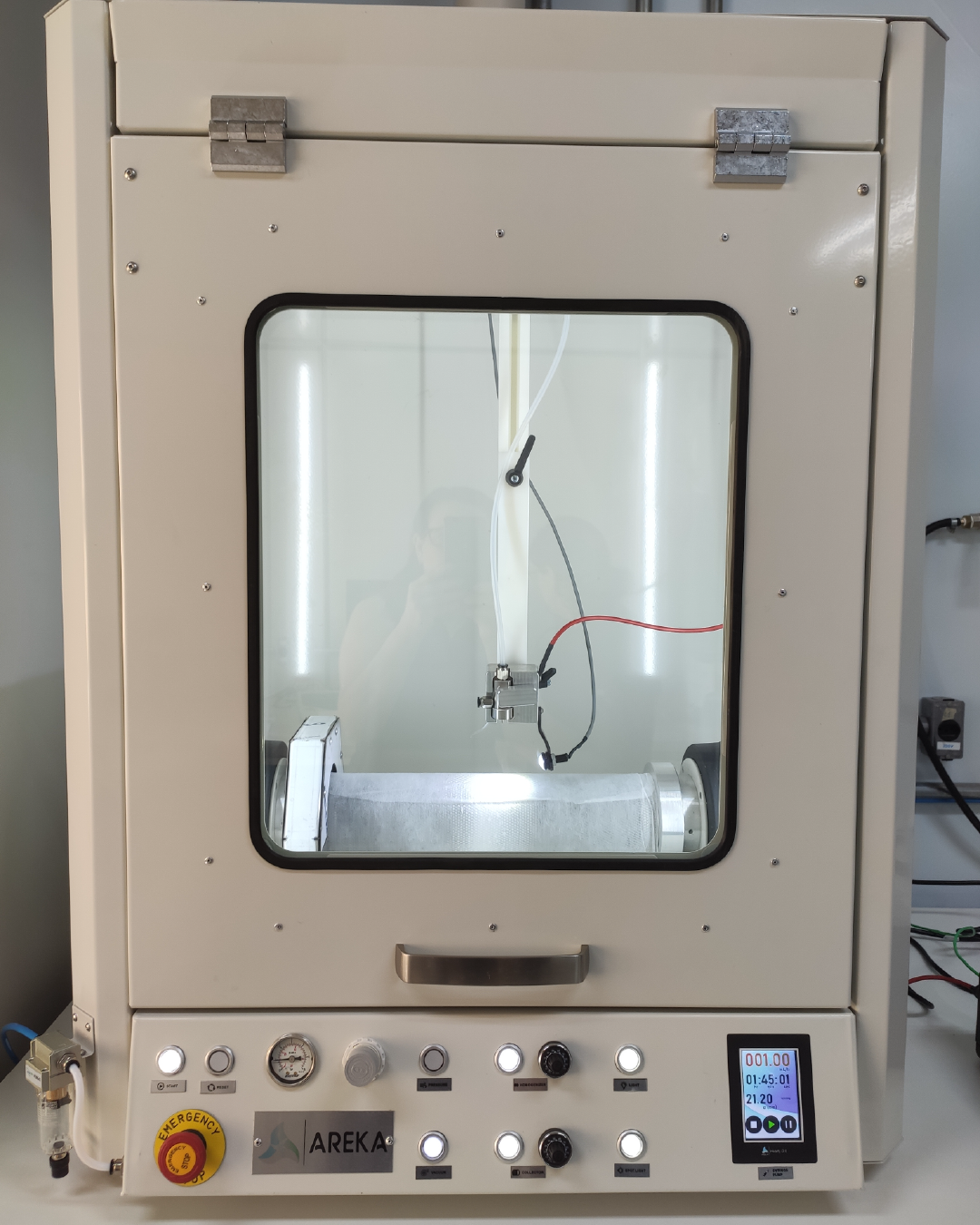

• 3-in-1 Electrospinning System: electrospinning, solution blow spinning, and electroblowing (AREKA);

• Benchtop Freeze Dryer LJJ02 (JJ Científica);

• Particle Size Distribution Analyzer S3550 (Microtrac);

• Mercury Porosimeter model AUTOPORE IV 9500 (Micromeritics);

• Zeta Potential Analyzer STABINO (Particle Metrix GmbH);

• Elastic Modulus Measurement Equipment via Impulse Excitation Technique (Sonelastic);

• Differential Scanning Calorimetry (DSC) model Q20 (TA Instruments);

• Simultaneous Thermal Analysis TG-DSC/DTA model STA 449 F3 Jupiter (Netzsch);

• Dynamic Mechanical Analyzer – DMA 242 E/1/G (Netzsch);

• FT-Raman Spectrometer model RFS-100/S (Bruker);

• Mechanical Testing Machine model DL10000, EMIC (load cells 5KN and 100KN);

• Universal Testing Machine model 5584P (Instron, load cells 5KN and 150KN);

• Rockwell Hardness Tester;

• Vickers Hardness Tester;

• Brinell Hardness Tester;

• Sintering Furnaces (operating temperature 1700 °C) – Lindberg Blue;

• Muffle Furnaces (operating temperature 1200 °C) – EDG;

• Certified Universal Testing Machine for tests up to 100 tons;

• Asphalt Pavement Testing Machine.

Additionally, it is worth highlighting that the Petroleum Refining Catalysts Laboratory was established through a UNIVAP/Petrobras partnership and is equipped for Catalyst Evaluation and Production, with investments exceeding 3 million BRL. Some of the equipment in this laboratory include:

• BET Surface Area Analyzer (Nova2200e, Quantachrome);

• Surface Area Analyzer (Meso 400, JWGB);

• Chembet Analyzer (3000 TPR/TPO, Quantachrome);

• Gas Chromatograph (GC 2014, Shimadzu);

• Dynamometer (LTCM-100, Chatillon);

• Rheometer (Rheo 100, Plastech);

• Inorganic Compounds Synthesis Unit with jacketed reactor, dosing pump, mechanical stirrer, pH meter, temperature indicator, etc. (FGG 1000 and 2000 FGG).

PPGPM Proposal 2021–2024

Self-Assessment Report 2021–2024

Unified Regulations IP&D 2023

Re-enrollment Form

Enrollment Suspension/Cancellation Form

Qualifying Examination Committee

Thesis Defense Committee

Advising Form

Co-Advising Form

Final Presentation Form

Student Registration Form

External Member Registration Form

IP&D Calendar 2025

Class Schedule 2025 - 1st Semester

Class Schedule 2024 - 2nd Semester

Class Schedule 2024 - 1st Semester

Class Schedule 2023 - 2nd Semester

Class Schedule 2023 - 1st Semester

Class Schedule 2022 - 2nd Semester

Class Schedule 2022 - 1st Semester

Class Schedule 2021 - 2nd Semester

Class Schedule 2021 - 1st Semester

Currently, there are 23 active projects, distributed across the three current research lines:

• Synthesis and application of new materials and processes – all faculty members – aligned with all research lines;

• Development and characterization of micro and nanostructured systems for application in Photodynamic Therapy – Prof. Dr. Andreza Ribeiro Simioni – aligned with the Biomaterials and Nanotechnology research line;

• Study and characterization of mortars with the incorporation of particulate materials – Prof. Dr. Erika Peterson Gonçalves – aligned with the Industrial Technologies for Aeronautical, Environmental, Civil, Chemical, Automotive, and Related Applications research line;

• Controlled drug delivery systems – Prof. Dr. Erika Peterson Gonçalves – aligned with the Biomaterials and Nanotechnology research line;

• Development of hybrids and composites – Prof. Dr. Erika Peterson Gonçalves – aligned with the Properties and Processes of Materials and Composites: Metals, Ceramics, and Polymers research line;

• Formulation and characterization of hydrogels and bioinks for bioprinting – Prof. Dr. Fernando dos Santos Ortega – aligned with the Biomaterials and Nanotechnology research line;

• Reuse of grinding sludge for the manufacture of hard metal components (NbC-Wc-Ni) – Prof. Dr. Fernando dos Santos Ortega – aligned with the Properties and Processes of Materials and Composites: Metals, Ceramics, and Polymers research line;

• Development of Special Concretes – Prof. Dr. Fernando dos Santos Ortega – aligned with the Industrial Technologies for Aeronautical, Environmental, Civil, Chemical, Automotive, and Related Applications research line;

• Development and characterization of calcium aluminate cement-based blends for bone repair, Absorbable Grafts with Bioactive Properties for Complex Bone Reconstructions, and Production and characterization of biomaterials and biocomposites as grafts for bone regeneration in the form of lyophilized or bioprinted scaffolds, microspheres, or nanofibers – Prof. Dr. Ivone Regina de Oliveira – aligned with the Biomaterials and Nanotechnology research line;

• Development of biodegradable polymer production processes for use in packaging and medicine – Prof. Dr. José Geraldo da Cruz Pradella – aligned with the Properties and Processes of Materials and Composites: Metals, Ceramics, and Polymers research line;

• Production of jet engine biofuel using the organic fraction of urban waste through biotechnology and chemical catalysis – Prof. Dr. José Geraldo da Cruz Pradella – aligned with the Industrial Technologies for Aeronautical, Environmental, Civil, Chemical, Automotive, and Related Applications research line;

• Synthesis and characterization of nanopharmaceuticals for the diagnosis and treatment of diseases – Prof. Dr. Leandro José Raniero – aligned with the Biomaterials and Nanotechnology research line;

• Double-layer polypyrrole coating and its corrosion protection – Prof. Dr. Liu Yao Cho – aligned with the Properties and Processes of Materials and Composites: Metals, Ceramics, and Polymers research line;

• Chemical and electrochemical deposition of polypyrrole on conductive surfaces and applications – Prof. Dr. Liu Yao Cho – aligned with the Industrial Technologies for Aeronautical, Environmental, Civil, Chemical, Automotive, and Related Applications research line;

• Production of multifunctional coatings for high performance as solid lubricants and corrosion protection for aerospace components and study of the electric potential of surfaces charged by static electricity – Prof. Dr. Lucia Vieira – aligned with the Industrial Technologies for Aeronautical, Environmental, Civil, Chemical, Automotive, and Related Applications research line;

• Production of multifunctional coatings for high performance as solid lubricants and corrosion protection for biomedical devices and applications of superabsorbent polyacrylonitrile polymers – Prof. Dr. Lucia Vieira – aligned with the Biomaterials and Nanotechnology research line;

• Controlled drug delivery systems – Prof. Dr. Milton Beltrame Junior – aligned with the Biomaterials and Nanotechnology research line;

• Synthesis and identification of substances of commercial or regulatory interest – Prof. Dr. Milton Beltrame Junior – aligned with the Industrial Technologies for Aeronautical, Environmental, Civil, Chemical, Automotive, and Related Applications research line;

• Studies and optimization of metal alloys for applications in products and/or processes of the Aeronautical and/or Automotive Industry and processing and studies of materials for new and existing technologies in the Petroleum and Petrochemical Industry – Prof. Dr. Paulo Henrique Salles de Carvalho – aligned with the Industrial Technologies for Aeronautical, Environmental, Civil, Chemical, Automotive, and Related Applications research line.

The PPGPM maintains its research lines and projects in proper alignment with the professional master's modality, ensuring balanced distribution among the lines, faculty members, and projects.

Companies and Institutions with Direct Collaboration with PPGPM

• Bioactive Innovative Bioengineering

• Bioreset Biotecnologia Ltda.

• Bizu Tecnologias Aeroespaciais e Serviços Ltda.

• Brats Indústria e Comércio de Produtos Metálicos Especiais Ltda.

• Clarity Importação e Exportação de Vidros Ltda.

• Feitoglass Comercial Ltda.

• Forza Composite Tecnologia em Materiais Compósitos Ltda.

• Greenway World Solutions

• GVC Construções Ltda.

• IMAE – Inovação em Mecânica, Aeronáutica e Energia Ltda.

• National Institute for Space Research – INPE

• Instituto Granado de Tecnologia em Poliacrilonitrila – IGTPAN

• LM Farma Indústria e Comércio Ltda.

• L&M Prestação e Exportação de Serviços de Engenharia e Treinamentos Técnicos Ltda. (Pensa)

• LHcolus Tecnologia Ltda – EPP

• Lodorat Cosméticos Ltda.

• Mankiewicz Gebr. & Co

• Monsanto do Brasil Ltda. (Bayer)

• Osorio e Osorio Engenharia Ltda.

• Ozone & Life Indústria, Comércio e Sistemas Ltda.

• Technology Park of São José dos Campos

• Penetron Brasil Indústria e Comércio de Produtos para Construção Ltda.

• Psyche Aerospace Serviços de Tecnologia Ltda.

• Profissional Indústria e Comércio Ltda.

• Selaz Indústria e Comércio de Aparelhos Biomecânicos Ltda.

• University of Minho (Portugal)

• Weerulin do Brasil Refratários Especiais Ltda.

BRING YOUR COMPANY TO BECOME THE NEXT PPGPM PARTNER.

1 / 24

1 / 24

2 / 24

2 / 24

3 / 24

3 / 24

4 / 24

4 / 24

5 / 24

5 / 24

6 / 24

6 / 24

7 / 24

7 / 24

8 / 24

8 / 24

9 / 24

9 / 24

10 / 24

10 / 24

11 / 24

11 / 24

12 / 24

12 / 24

13 / 24

13 / 24

14 / 24

14 / 24

15 / 24

15 / 24

16 / 24

16 / 24

17 / 24

17 / 24

18 / 24

18 / 24

19 / 24

19 / 24

20 / 24

20 / 24

21 / 24

21 / 24

22 / 24

22 / 24

23 / 24

23 / 24

24 / 24

24 / 24

AV. SHISHIMA HIFUMI, 2911 - URBANOVA - SÃO JOSÉ DOS CAMPOS - SP - FONE:(12) 3947-1000

Boleto

Reportar erro!

Comunique-nos sobre qualquer erro de digitação, língua portuguesa, ou de uma informação equivocada que você possa ter encontrado nesta página:

Por Redação, em Master's and Doctorate